Select a Part:

Frame

Table

Spindle

Ways

Drive

CNC Controller

Accessories

This Guide to DIY CNC Router Parts is designed for exploration and learning. This page is the home page and visual table of contents. Click the menu above to scroll to a particular part of a typical CNC Router. You'll get a brief overview of the part together with links that let you drill down and discover more detail about the CNC Router Part.

Use the Guide as an aid to help you make good design choices for your own DIY CNC Router project.

Frame

The frame supports the machine and provides rigidity to resist cutting forces. For larger routers, there may be a stand with legs or a welded base. Smaller models sit on top of a bench.

CNC Milling Machine Frames are most commonly made of aluminum extrusions. Other possibilities include aluminum plate, steel weldments, or even wood. To get an idea of a really stout frame that could be made of steel weldments and epoxy granite fill, click the link.

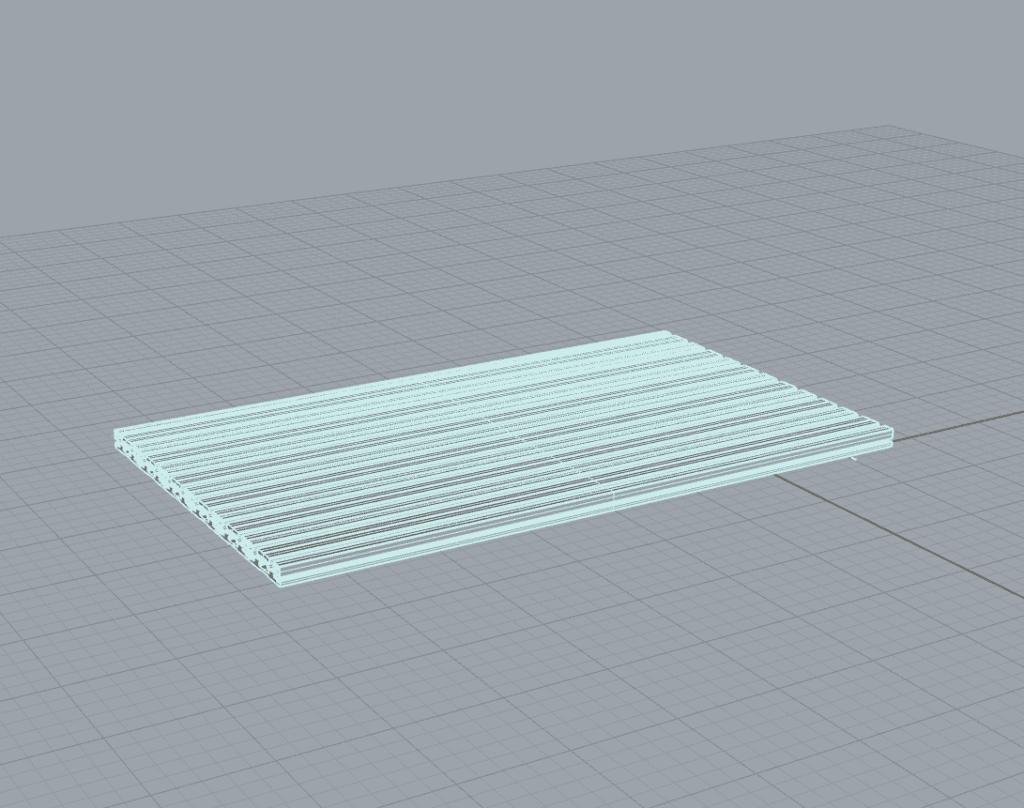

Table

CNC Router Tables can be made from a lot of materials. Shown are aluminum extrusions set up to create T-Slots. A router table might also be made of an expendable material like MDF. In that case, if it is intended to be expendable and replaced when needed, it is usually called a spoilboard or wasteboard.

CNC Router Tables may be bare, but often they will have features to facilitate workholding. For example, T-Slots, a hole grid, or a vacuum table are common.

Wood tops are sensitive to moisture. In fact they can swell enough to cause accuracy issues for the CNC Router. For that reason, aluminum, steel, or phenolic are commonly found on higher end machines. A wooden spoilboard may then be attached atop the tough table below.

Spindle

Some say the Spindle is the heart of any CNC Machine. It certainly plays a major role in setting the performance potential of the machine.

At the low end, CNC Routers often use regular hand held routers or even Dremel-style tools as spindles. A step up from that is a spindle with a VFD. At the top of the heap are spindles set up for ATC-Automatic Tool Changers.

Ways

CNC Routers have at least 3 Axes. An axis consists of some kind of sliding "ways" and a drive system that motorizes the axis under computer control.

There are several kinds of sliding ways commonly used for CNC Routers:

V-Grooves involve using ball bearings with wheels that often have a v-shaped groove in them. These wheels ride on the edge of a rail of some kind. The rail could be a triangular edge on an extrusion, or perhaps the edge of a piece of angle iron or something similar. The groove in the wheel need not be V-Shaped, it could also be cupped, for example to ride on a piece of round shaft or a curved edge.

V-Grooves are the cheapest kind of sliding way, but they're also the least accurate and most prone to backlash. The often require adjustment at frequent intervals for best performance.

Round shafts are what's depicted in our photos of a CNC Router. They use ball bearings and can be quite a bit better performers. The highest performance are linear slides, which have a prismatic shape and trucks that ride on ball bearings.

Axis Drive

The CNC Router's Axis Drive system converts rotary motion from a motor of some kind to linear motion to drive the axis on its sliding ways.

There are several common Axis Drive system in use for CNC Routers:

When choosing your drive system, a number of factors must be considered:

- Conversion of the motor's torque to rapid movement speed at the rpm where the motor's torque peaks.

- Elimination of backlash or lost motion, which can reduce the accuracy of cutting as well as lead to other problems.

- Cost

- More specialized issues such as ballscrew whipping on long axes.

We offer detailed articles on CNC Rack and Pinion drives and also on Ball Screws to help.

Also part of the drive system are the motors, and any drive connecting the motors to the rest of the drive. Motors are most commonly stepper motors, but servos are a higher performance option.

CNC Controller

A CNC Router's Controller is the electronics package that is responsible for executing a g-code programming and sending the necessary electrical signals to cause the motors to move properly to cut the part.

There is a wide variety of CNC Controllers out there for CNC Routers. Pictured is Tormach's PathPilot, which is used on their whole line of CNC Machines. It's quite powerful and easy to use.

Another very common controller is GRBL. GRBL is open source software that runs on an Arduino single board computer. It's UI runs on your PC.

Controllers can be largely single board without interface to a PC, single board with interface to PC (the UI runs on the PC), or based entirely on a PC with potential accessory boards for motion control. There will also be a DC power supply to run the motors, drivers for the motors, and various other electronics for things like Limit Switches or spindle control.

Ready to Learn More About CNC Routers?

You need our CNC Router Buyer's Guide. It is your complete guide to all the best CNC Routers on the market.

CNC Router Accessories

Software

The basic software suite for wood CNC machine users generally consists of the following:

- CAD Software: Use it to design the parts you want to make with your router.

- CAM Software: Feed it the CAD model of the part and CAM software will produce a g-code program your CNC Router can run to make the part.

- Feeds and Speeds Software: Every cutting tool, material, and situation demands a different recipe for feeds (how fast the cutter is fed into the material) and speeds (what rpm the spindle is running). Make sure your Feeds & Speeds software is setup for CNC Routers. You can't use just any old Feeds and Speeds program because routers have different needs.

You will want to cover all three bases.

Workholding

It's essential to secure hold your workpiece while cutting it. The methods and tooling for doing this are collectively referred to as "Workholding."

The photo shows a spoilboard with a grid of holes in it. A Threaded Insert goes in each hole. Now you have a grid of holes that create a Fixture Plate. You can install clamps, workstops, and other workholding devices by bolting them down to the holes.

For more information on CNC Router Workholding, see our article via the link.

Special Cutters

What router bits should I use? First, use any standard CNC endmill that works for wood or the material you're cutting. The manufacturer will tell you what materials are an option for their cutters.

Second, avoid most hardware store cutters intended for routers. CNC Routers are a different beast, even though they may even use a standard router for a spindle.

Last, learn about the special cutters that are available for CNC Routers. Click through the link to see our article on them.

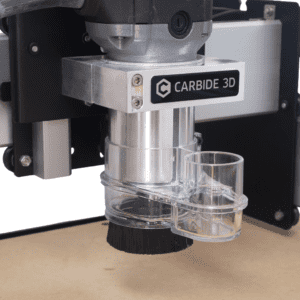

Dust Collection

CNC Routers are designed to turn whatever they're cutting into chips in a hurry. In other words, they produce a LOT of dust. So much, that cleanup is a problem. Sometimes even breathing can be a problem. The answer is Dust Collection. Even a simple dust boot connected to your ShopVac will help tremendously.

The photo below shows "Sweepy", a dust boot that lets you connect your ShopVac to suck up the dust on a Shapeoko CNC Router. They make Sweepy in sizes that correspond to commonly used trim routers.

For more on dust collection check out our detailed article, "Shop Vac vs Dust Collector: Easy Guide."

Misters and Coolant Sprays

If you plan on cutting aluminum with your CNC Router, you should invest in a mister. Aluminum tries to weld chips to CNC Cutters, and the end result is a broken cutter wrapped with melted aluminum that looks like taffy. Many will tell you they've gotten away with cutting aluminum without any form of lubricant, but it's a game of chance and the odds are against you unless you use a Mister.

It's pretty easy to buy or build a mist system for your CNC Router. Here's our article describing a Coolant Mister I cobbled together from parts off eBay.

You can also buy one ready to go pretty darned cheaply. Here's one for about $20 on Amazon:

Add a coolant reservoir (I saw one made from a sports water bottle!) and feed it a little compressed air and you're up and running.

Tool Setters and Touch Probes

Shapeoko BitZero...

Automatic Tool Setters and Touch Probes make it easy to tell your CNC Controller how long your tool is and where you're parts 0, 0 coordinate is. These are both things it needs to know before it can start cutting accurately.

Pictured is the Shapeoko Bit Zero. Another great product is The Maker's Guide Triple Edge Finder.

Be the first to know about updates at CNC Cookbook

Join our newsletter to get updates on what's next at CNC Cookbook.